A maintenance backlog refers to the accumulation of work orders or tasks that haven’t been completed within their expected timeframe. While a manageable backlog can help prioritize work, an out-of-control backlog can strain resources, increase costs, and lead to costly equipment failures.

Keeping your maintenance backlog in check requires a structured approach to planning, scheduling, and execution. Many plants recognize that, as WO backlog is the second most tracked maintenance KPI in industrial facilities.

In this article, we’ll show you how to calculate your backlog, identify when it’s too large, and provide actionable tips to keep it under control.

How to calculate your maintenance backlog

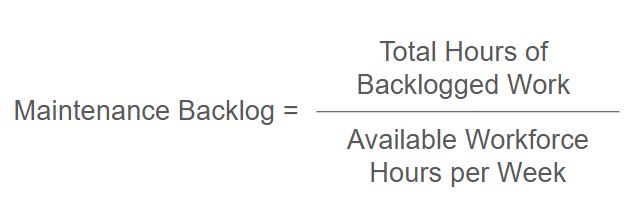

Calculating your backlog involves a simple formula that helps you gauge how much outstanding work your team has relative to its capacity.

Here’s the maintenance backlog calculation formula:

This calculation gives you a clear ratio of how many weeks’ worth of work your team has lined up.

Quick example: Let’s say your team has 800 hours of backlogged work, and your available workforce can provide 400 hours of labor each week. We can simply apply the maintenance backlog calculation formula:

Maintenance Backlog = (Total Hours of Backlogged Work) / (Available Workforce Hours per Week)

Maintenance Backlog = 800 / 400

Maintenance Backlog = 2 weeks

This means your current backlog represents two weeks of work for your team, assuming no additional tasks are added during that period.

By tracking your backlog regularly, you’ll have a better sense of whether your workload is manageable or if adjustments need to be made to your resources or processes. A backlog that continues to grow without control is a clear sign of inefficiencies that need to be addressed.

Maintenance backlog benchmark: How much backlog is too much?

A maintenance backlog isn’t inherently bad — in fact, having some backlog is a sign of an organized system that prioritizes work based on importance and urgency. The problems start when it grows too large.

Industry benchmarks typically recommend that a manageable backlog should represent 2–3 weeks of work for your maintenance team. This range allows enough flexibility to handle emergencies while ensuring that routine maintenance and planned work can proceed smoothly.

That said, the maintenance backlog benchmark can vary by industry. For example, in utilities and energy, a backlog of 4–6 weeks is often acceptable because long lead times and strict regulatory requirements make extended planning cycles more practical. In contrast, facilities management typically aims for a tighter 2–3 week backlog to prioritize occupant comfort and safety, where faster turnaround is critical.

The ideal backlog size for your team will depend on your team’s capacity, the criticality of assets, and the volume of incoming work. For example:

- Too small (<1 week): Indicates your team might not have enough work planned or you’re heavily reliant on reactive maintenance, which can increase costs and risks.

- Too large (>4 weeks): Suggests inefficiencies, such as poor scheduling, resource constraints, or excessive delays in procuring materials or vendor services.

How do you recognize that you have a problem? Here are some signs of an out-of-control maintenance backlog:

- You’re starting to regularly see work orders that are older than 30 days.

- Your Maintenance Schedule Compliance (the percentage of scheduled tasks completed on time) is going down.

- Your maintenance team is perpetually in “firefighting mode”, unable to complete preventive tasks.

When these signs appear together, it’s time to make some changes.

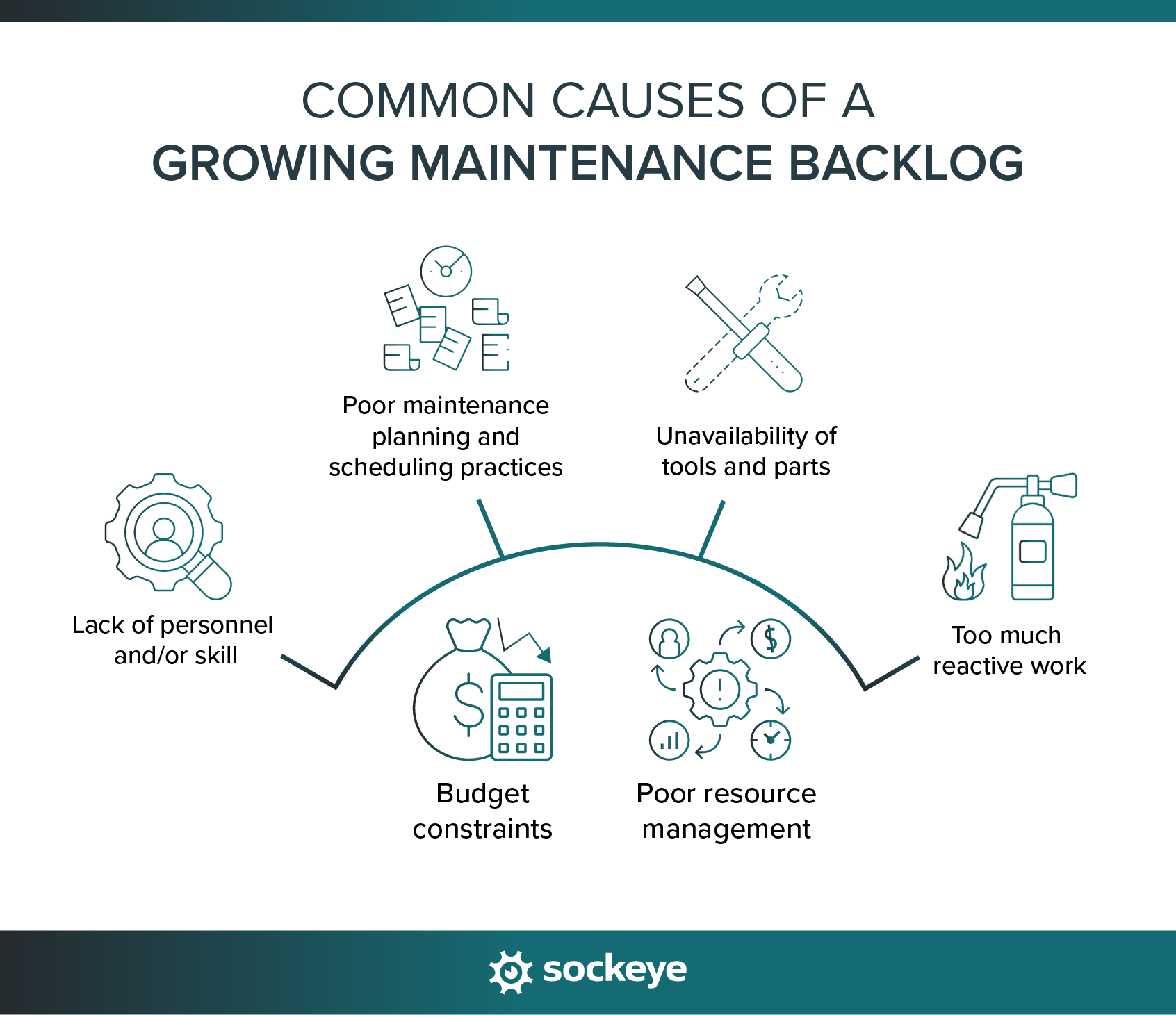

Causes and solutions for a growing maintenance backlog

Budget constraints and poor resource management are the two core issues behind most maintenance delays. While increasing your budget is not always a viable option, every maintenance team can work on getting more organized.

Below, we discuss the leading causes behind growing backlogs — and what you can do about them.

Lack of personnel and/or skill

When skilled technicians are scarce, complex maintenance tasks often get pushed back while the available personnel handle only the most urgent issues. This creates a snowball effect where routine maintenance becomes increasingly backlogged.

Here’s how you start solving challenges related to a lack of labor:

- Get your staff trained on multiple types of equipment so they can handle various repairs without waiting for specialists.

- Partner with technical schools to create apprenticeships, and develop workers for your future needs.

- Develop comprehensive documentation and standard operating procedures to help less experienced technicians perform maintenance tasks correctly.

- Train select machine operators to help with basic maintenance work like lubrication (also known as autonomous maintenance).

- Invest in predictive and condition-monitoring tools to optimize your maintenance workloads.

Sockeye software helps you get more from your existing team in two big ways:

- By streamlining maintenance scheduling. When weekly scheduling takes minutes instead of hours, your team has more time to create better job plans, set realistic schedules, and properly prioritize work.

- Our scheduling automation, combined with real-time labor availability data, helps you level workload between teams while scheduling everyone near 100% capacity.

Unavailability of tools and parts

Poor inventory management often leads to maintenance delays when required spare parts or tools aren’t available. This happens due to inadequate tracking systems, inaccurate forecasting, or budget constraints that limit inventory levels.

Use these tips to maintain proper spare parts inventory:

- Implement a digital inventory management system that tracks usage patterns and automatically triggers reorders (most modern CMMS solutions can do that).

- Develop relationships with multiple suppliers to ensure part availability.

- Create a critical spare program that ensures essential parts are always in stock.

- Standardize the equipment you are using where possible to reduce the variety of parts you need.

When parts or tools aren’t available, even simple maintenance tasks can be postponed indefinitely. If the budget is not an issue, this should rarely happen.

Poor maintenance planning and scheduling practices

Poor planning and scheduling create chaos in maintenance work. It leads to teams deferring tasks because they lack clear systems for setting priorities, coordinating work, and managing time — not (just) because they lack resources.

Become better at planning, scheduling, and organizing maintenance work by:

- Establishing clear criteria for maintenance prioritization.

- Creating detailed maintenance procedures and time estimates for common tasks.

- Following maintenance planning best practices.

- Following maintenance scheduling best practices.

- Using maintenance metrics to track performance and identify scheduling bottlenecks.

- Using work order scheduling software like Sockeye to automate and simplify your scheduling process.

Sockeye directly addresses these challenges by providing a structured framework for maintenance scheduling. It connects to your CMMS or SAP to help you prioritize work, maintain detailed records, and coordinate your team and resources effectively. Here’s how it works:

Too much reactive work

Emergency repairs trap maintenance teams in a vicious cycle. When teams rush from one breakdown to another, they push aside scheduled maintenance. This neglect triggers more breakdowns, leaving even less time for planned work.

Here’s how to break free from this cycle:

- Gradually increase preventive maintenance activities to reduce emergency repairs.

- Implement condition monitoring to catch potential failures before they occur.

- Analyze failure patterns to identify and address root causes.

- Set targets for the ratio of planned vs. unplanned work so you can benchmark performance.

- Create dedicated teams for reactive work to protect planned maintenance time.

Try to track which equipment breaks down most often and what are the identified causes. Then sort the assets based on their criticality. The ones that top the list are usually the assets you want to put in your preventive maintenance plan first.

Additional maintenance backlog management tips

We were not able to squeeze all of our advice into the previous section, so here are two additional practical tips to streamline maintenance backlog management.

As Don Armstrong notes in Reliable Plant article, effective backlog management is essential:

Split your backlog into categories

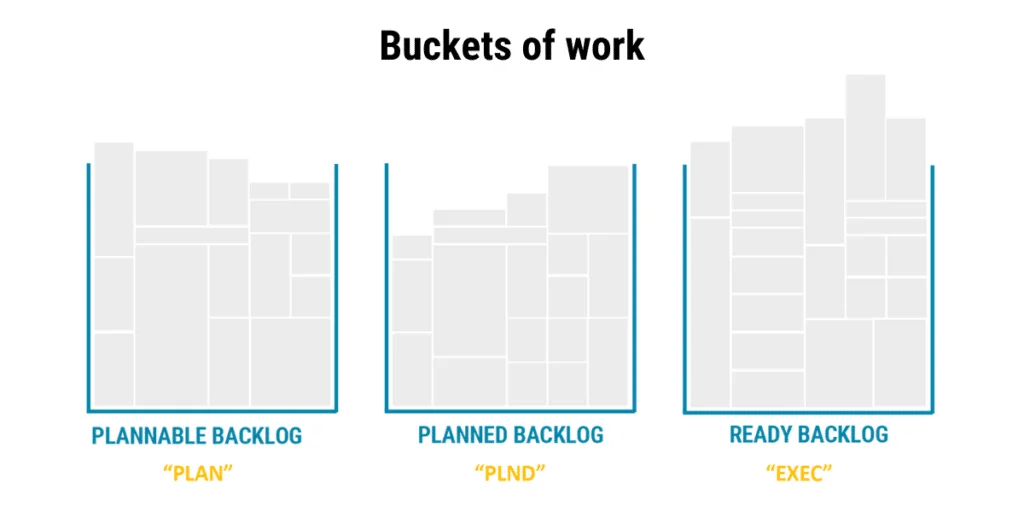

If you are leading a big team, Erik Hupjé from the Reliability Academy recommends splitting your backlog into three different “buckets of work”:

- Plannable backlog: Tasks that still need to be planned or are in the process of being planned. These jobs are owned by the planner and often require more details, such as scoping, defining materials, or clarifying labor requirements.

- Planned backlog: Tasks that have been fully planned but aren’t ready to be executed yet. The reasons might include waiting for materials to arrive, confirming contractor availability, or scheduling special tools or equipment.

- Ready backlog: Tasks for which all materials, resources, and approvals are in place, and the scheduler can fit them into the work schedule at any time. This backlog is owned by the scheduler and represents work that’s ready to go.

An example of categorizing backlog work.

By doing this, you align tasks with the specific stages of your maintenance planning and scheduling process.

If one category consistently overflows, it highlights a bottleneck in that part of the workflow. For instance, if the “Planned Backlog” is overloaded, it might signal delays in procuring materials or confirming vendor schedules.

Create a deferred maintenance plan to reduce your backlog

There’s a quote attributed to a French writer and journalist, Antoine de Saint-Exupéry, who said: “A goal without a plan is just a wish.”

It applies quite well in this context. You can say that you want to clean out X hours of work from your backlog over Y months, but you will need a structured process to actually get there.

Check out our step-by-step guide for creating a smart deferred maintenance plan for more information.

Keep your deferred maintenance backlog in check with Sockeye

Managing a maintenance backlog requires organization, visibility, and efficient workflows — all of which Sockeye helps you achieve through:

- Organized backlogs: Sockeye allows you to categorize and track maintenance work by status, priority, asset type, and other characteristics. You’ll have a clear view of ready-to-schedule work at all times.

- Smart scheduling: Sockeye helps you easily track and update labor availability (someone is training, sick, short 2 hours on Friday, etc.). Our automation then builds a weekly/daily schedule that tracks the % of labor scheduled — maximizing scheduled work.

- Improved collaboration: Sockeye provides a single source of truth for planners, schedulers, and operations/production, reducing delays caused by miscommunication or missed updates.

- Delay codes: You can track why work was postponed (missing parts, weather, asset unavailable, etc.) using Sokeye’s delay codes. This can help you identify operational inefficiencies and root causes behind a growing backlog.

- Data-driven insights: With robust KPI reporting and analytics, Sockeye helps you identify bottlenecks in your workflow, track deferred maintenance trends, and make informed decisions to optimize your operations.

Ready to take control of your maintenance backlog? Schedule a demo today and see how Sockeye can help your team work smarter, not harder!