Maintenance management is a lot of work. Any business that relies on equipment, facilities, or assets to function smoothly must have a system in place to plan, schedule, and track maintenance work.

Many businesses start with Excel to manage maintenance tasks — it’s familiar, flexible, and cheap. But as operations grow, spreadsheets can quickly become a bottleneck. That’s where a Computerized Maintenance Management System (CMMS) can help. They offer automation, centralized data, and advanced reporting that promises to streamline operations.

But CMMS solutions are not without their quirks. They can be rigid and hard to use, especially when it comes to maintenance scheduling. Despite being a heavy favorite, they are not a clear-cut winner in every CMMS vs. Excel debate.

Let’s look at what they struggle with, where they excel (pun intended), and what their best use-case scenarios are.

Before that, one important caveat.

The problem with evaluating CMMS solutions

If you want to use spreadsheets for maintenance management, you don’t have a lot of options. Google Sheets and Excel are the two top choices, and their capabilities are pretty much the same.

That is not the case with a CMMS. There are hundreds of different CMMS providers out there, and their implementations vary wildly. We have seen different factories using SAP, on-premise legacy systems built 30+ years ago, and modern CMMS solutions.

Furthermore, their marketing materials rarely match the end user experience. They all flaunt how easy to use they are, but the existence of a CMMS bolt-on like Sockeye shows that is not always the case.

So, what you are going to see below is a comparison between an Excel and an average CMMS experience. In other words, you can find CMMS solutions that perform better — and those that perform worse — than what we state in this article.

CMMS vs Excel spreadsheets for maintenance management

A modern CMMS is a cloud-based, centralized platform for all things maintenance. Key features include work request portal, work order management, maintenance scheduling, asset tracking, parts inventory management, reporting, and analytics.

Excel is a go-to solution for businesses that want a simple way to track maintenance activities without investing in specialized software. Teams typically create spreadsheets to log work orders, maintenance schedules, and asset details. Some businesses use formulas, pivot tables, or even macros to automate basic tasks and generate simple reports.

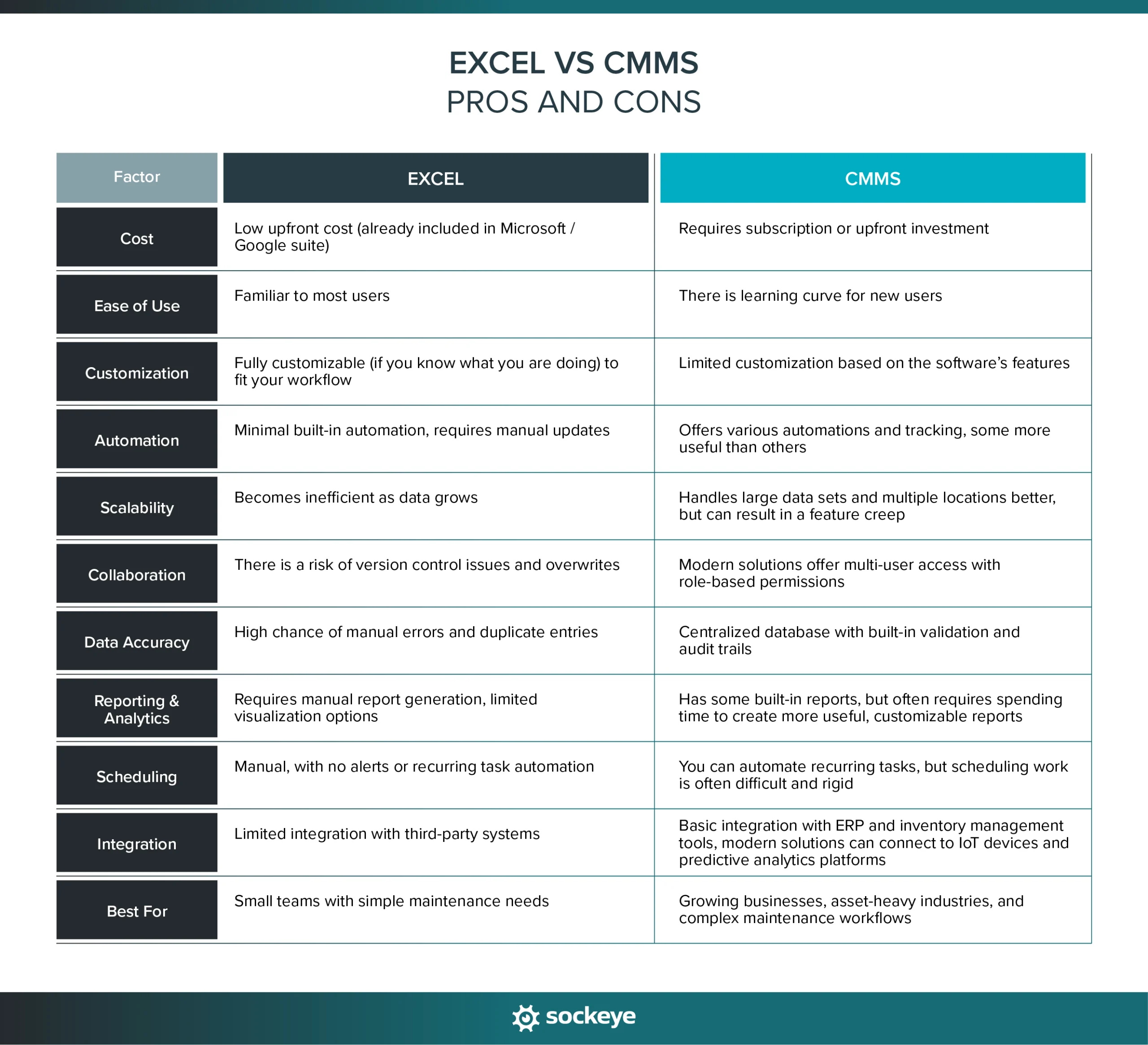

Below, we’ll compare them in key areas: ease of use, data management, scheduling, scalability, reporting, and cost.

If you just need a quick overview, we have a comparison table:

Ease of use

When choosing a tool for maintenance management, ease of use is a major factor. A system that’s too complex can slow teams down, while a lack of features can lead to inefficiencies. Let’s see how they stack up.

User interface & learning curve:

- Excel: Most people are already familiar with spreadsheets, making it easy to start logging maintenance tasks. However, as data grows, sheets become cluttered, requiring users to master formulas, conditional formatting, and macros for efficiency.

- CMMS: Designed for maintenance teams, CMMS platforms typically have nicer interfaces and dashboards. However, there can be a steep learning curve. To remedy that, many CMMS providers offer training guides, videos, and weeks-long hands-on training sessions.

Setup & customization:

- Excel: Customization is entirely manual — users must build their own tables, formulas, and automation rules. While this allows for more flexibility, it can be time-consuming and prone to errors. That said, in contrast to implementing CMMS, starting with Excel requires minimum involvement from your IT department.

- CMMS: Most platforms come preloaded with different templates, asset tracking modules, and automated workflows. While you are not starting from scratch, and there is some flexibility, most CMMS will push you to follow a specific workflow, whether that works for your team or not.

Accessibility & collaboration:

- Excel: Collaboration in Excel is possible through cloud storage (e.g., OneDrive, Google Drive). However, real-time editing can be slow, and version control issues often arise. Spreadsheets are also prone to accidental deletions or overwrites.

- CMMS: With CMMS, you often get role-based access, allowing maintenance managers, technicians, and executives to access relevant data. Modern CMMS platforms are cloud-based, making them accessible from desktops, tablets, and mobile devices, ensuring real-time updates.

Data management and accuracy

Accurate data is critical for effective maintenance management. Mistakes, duplicate entries, and missing information can lead to downtime, missed work orders, or compliance issues.

Data entry and management:

- Excel: Users must manually enter and update data. While formulas can automate some calculations, human error is common — especially when multiple users edit the same spreadsheet. Data can become inconsistent or lost if not carefully managed.

- CMMS: Automates some of the data entry by pulling in asset details, tracking work orders, and updating records in real time. Maintenance history, repair logs, and spare parts inventory are stored in a structured format, reducing the risk of errors.

Data centralization:

- Excel: Data is typically stored in separate spreadsheets, requiring users to switch between tabs or files to track different aspects of maintenance. This can create silos of information, making it difficult to get a clear overview.

- CMMS: Stores all maintenance data in one centralized database. Teams can access work orders, asset histories, inventory, and schedules in one place. That said, some solutions have poor navigation and search functionality, making things hard to find.

Audit trails & change tracking:

- Excel: Version control is a challenge. If multiple users edit a spreadsheet or make a copy, tracking changes can be difficult. While online spreadsheets offer some history tracking, they are not built for auditability.

- CMMS: While not perfect, tracking changes to work orders, asset details, and maintenance schedules is easier. This ensures accountability and allows teams to review past actions, especially useful for compliance and regulatory requirements.

Duplicate data prevention:

- Excel: Without strict data entry rules, it’s easy to create duplicate work orders, asset entries, or inventory records. This can lead to confusion and inefficiencies.

- CMMS: Uses built-in validation rules to prevent duplicate entries. Work orders and asset records are unique, ensuring data consistency and avoiding redundancy.

Maintenance scheduling

Effective maintenance scheduling keeps operations running smoothly, prevents unexpected downtime, and ensures compliance with preventive maintenance plans. Both Excel and CMMS can be used for scheduling, but their approaches are very different — and often lacking.

Automation in scheduling:

- Excel: Scheduling in Excel is entirely manual. Users must input dates, update task statuses, and create formulas to calculate due dates. While conditional formatting can highlight overdue tasks, there’s no true automation — someone must continuously monitor and update the spreadsheet. This is why maintenance teams are constantly looking for a better scheduling solution.

- CMMS: Gives you the ability to generate recurring work orders, assign tasks, and send alerts when maintenance is due. However, many teams find scheduling through CMMS cumbersome, turning to simpler maintenance work order scheduling solutions.

Work order management:

- Excel: Work orders are typically tracked in a table, with columns for due dates, assigned technicians, and task status. Updating records requires manual input, and managing multiple open tasks can become chaotic.

- CMMS: Provides a dedicated work order management system, where tasks can be assigned, tracked, and updated in real time. Technicians can log work directly into the system, attach photos (only some solutions allow this), and mark jobs as complete — all from a desktop or mobile device.

Alerts & notifications:

- Excel: No built-in notification system. Users must manually check schedules, and important tasks can be overlooked if reminders aren’t set up in external tools like Outlook or Teams.

- CMMS: Newer solutions can send automated notifications and alerts via email or app notifications to remind teams of upcoming maintenance tasks, overdue work, or urgent repairs.

Recurring tasks:

- Excel: Setting up recurring maintenance requires using formulas or copying and pasting rows for each occurrence. This can work fine on a small scale. Otherwise, it is time-consuming and prone to errors.

- CMMS: When you know what you are doing, setting up recurring tasks through a CMMS is quicker. However, this often requires ongoing training, as well as some trial and error.

Calendar integration:

- Excel: Can be integrated with calendars by exporting data or linking with external tools, but this requires effort and constant updates.

- CMMS: Certain solutions include a built-in maintenance calendar that syncs with Google Calendar, Outlook, or internal scheduling tools. You will have to double-check that with each provider.

Scalability and integration

As maintenance operations grow, so do the challenges of managing data, coordinating teams, and integrating with other business systems. Let us see how CMMS and Excel fare in this regard.

Handling large data sets:

- Excel: While Excel can store vast amounts of data, performance slows down as files grow larger. Searching for specific records, filtering work orders, or analyzing trends across thousands of rows can become cumbersome.

- CMMS Allows quick searches using various pre-defined filters, even as asset and work order records grow over time. That said, older CMMS solutions can also suffer from unresponsiveness and struggle with higher data loads.

Third-party integrations:

- Excel: Can integrate with other software using add-ons, VBA scripts, or manual data exports/imports. However, these solutions are often clunky and require ongoing maintenance.

- CMMS: Depends on the provider. On average, they offer basic integration with ERP systems and inventory management tools. Some can also connect to accounting solutions, IoT sensors, and platforms running predictive and prescriptive analytics.

Reporting and analytics

Accurate reporting is essential for tracking maintenance performance, reducing downtime, and making data-driven decisions.

Generating and sharing reports:

- Excel: Users can create reports by filtering data, using pivot tables, and generating charts. However, reports must be manually updated, which is time-consuming and leads to inaccuracies — compromising reporting (especially for large datasets). Data can be exported and shared easily via email or cloud storage.

- CMMS: You can pull available maintenance data into pre-built reports whose usefulness is debatable. If you take time to build customizable reports, you can schedule them to be generated and sent automatically. Unfortunately, due to perceived or actual complexity, most users never take the time to do that.

Visual dashboards:

- Excel: Dashboards require manual setup with charts, graphs, and conditional formatting. While Excel is powerful, creating a maintenance dashboard requires expertise in data visualization.

- CMMS: Modern solutions have customizable visual dashboards that display key metrics like work order completion rates, asset downtime, and maintenance costs. However, in most cases, you are stuck with basic charts and graphs, similar to Excel.

Cost considerations

Cost is a major factor when deciding between a CMMS and Excel for maintenance management. While Excel is more affordable upfront, there are other costs to consider.

Upfront costs:

- Excel: Most businesses already have access to Excel through Microsoft 365 or Google Sheets, making it a low-cost option in terms of license expenses.

- CMMS: CMMS platforms typically come with subscription fees (monthly or annual), which vary based on features, number of users, and deployment type (cloud-based vs. on-premise). Plus, you will have to involve your IT department to help with the setup, which can take significant effort (depending on your chosen CMMS provider).

While Excel appears cost-effective, several hidden costs can impact efficiency and profitability:

- Manual labor: Maintenance teams spend extra time entering data, updating schedules, and generating reports.

- Data errors: Mistakes in spreadsheets can lead to costly maintenance failures or unexpected downtime.

- Limited tracking: Without automated work orders and scheduling, critical maintenance tasks can be missed, again leading to costly downtime.

A CMMS requires an initial investment, as well as some time to update workflows and train your team. Organizations that successfully implement a CMMS often measure lower labor and inventory costs. Plus, smarter decision-making based on real-time data can lead to further cost savings by reducing downtime and improving productivity.

When to choose CMMS over Excel — and vice versa

Choosing between Excel and a CMMS depends on the size of your operation, budget, and maintenance needs. While a CMMS is the better long-term solution for most businesses, there are cases where spreadsheets might still be enough.

When Excel is sufficient

For small teams with simple maintenance needs, Excel can be a cost-effective option. If your maintenance tasks are minimal, and your team can easily track work orders without automation, a spreadsheet may work just fine.

Excel is also a good choice for businesses with tight budgets. If you only need basic maintenance tracking, it provides a quick and simple way to log tasks without additional software costs.

When CMMS is the better choice

As businesses grow, manual tracking in Excel becomes inefficient. A CMMS is the better choice for companies managing multiple assets, locations, and technicians. It’s also essential for asset-heavy industries like manufacturing, healthcare, utilities, and construction.

Switching to a CMMS should improve efficiency and accountability if your team struggles with missed work orders, data inconsistencies, or lack of reporting. For companies looking to scale operations and improve maintenance efficiency, a CMMS is a good investment.

Why do companies that have a CMMS still use spreadsheets to schedule work?

Even after implementing a CMMS, some companies still return to using maintenance schedule templates made in Excel. There are a couple of reasons why this happens.

The first, smaaller one, is that maintenance teams are used to working with Excel and find it hard to fully transition to a CMMS. If employees aren’t properly trained or don’t trust the new system, they may stick with familiar spreadsheets — better the devil you know mentality.

The biggest reason is that many CMMS solutions, even modern ones, have complex interfaces that make quick scheduling harder than just updating a spreadsheet. They add a bunch of functionality that can be great for specific scenarios, but most teams will never use.

And if a CMMS’s scheduling doesn’t fit a company’s workflow, teams supplement it with Excel for convenience. They still continue using their CMMS for many other things like capturing work requests or tracking inventory, assets, and costs.

But what if we told you that there is a better way and you don’t need to fall back to Excel for maintenance scheduling? Introducing Sockeye.

Use Sockeye — the only CMMS bolt-on for maintenance scheduling

For companies struggling with scheduling in their CMMS, Sockeye offers a simple solution. Instead of switching between spreadsheets and CMMS software, simply connect Sockeye to your CMMS and use our intuitive scheduling interface instead.

You can schedule work based on real-time information about technician qualifications and availability, reactive work, and current workloads. You can even let Sockeye’s automation build daily/weekly schedules for you — then review and edit them as needed before publishing.

Instead of telling you everything Sockeye can do, let us show you instead with this 90-second video:

Want to try Sockeye out? Schedule a demo today. If you like what you hear, our team will set you up with a test environment.

This requires no investment or IT resources — just a few hours from the scheduler. You will be able to verify that Sockeye is right for you without spending a single penny.