When it comes to maintenance management, two roles often get confused: maintenance planner and maintenance scheduler. While they work closely together, their responsibilities are quite different.

In this article, we’ll break down what each role does, how they coordinate, and why separating them can improve efficiency. We’ll also discuss the key skills required for each position and highlight how tools like Sockeye can help schedulers stay on top of their work.

Maintenance planner and scheduler: One or multiple roles?

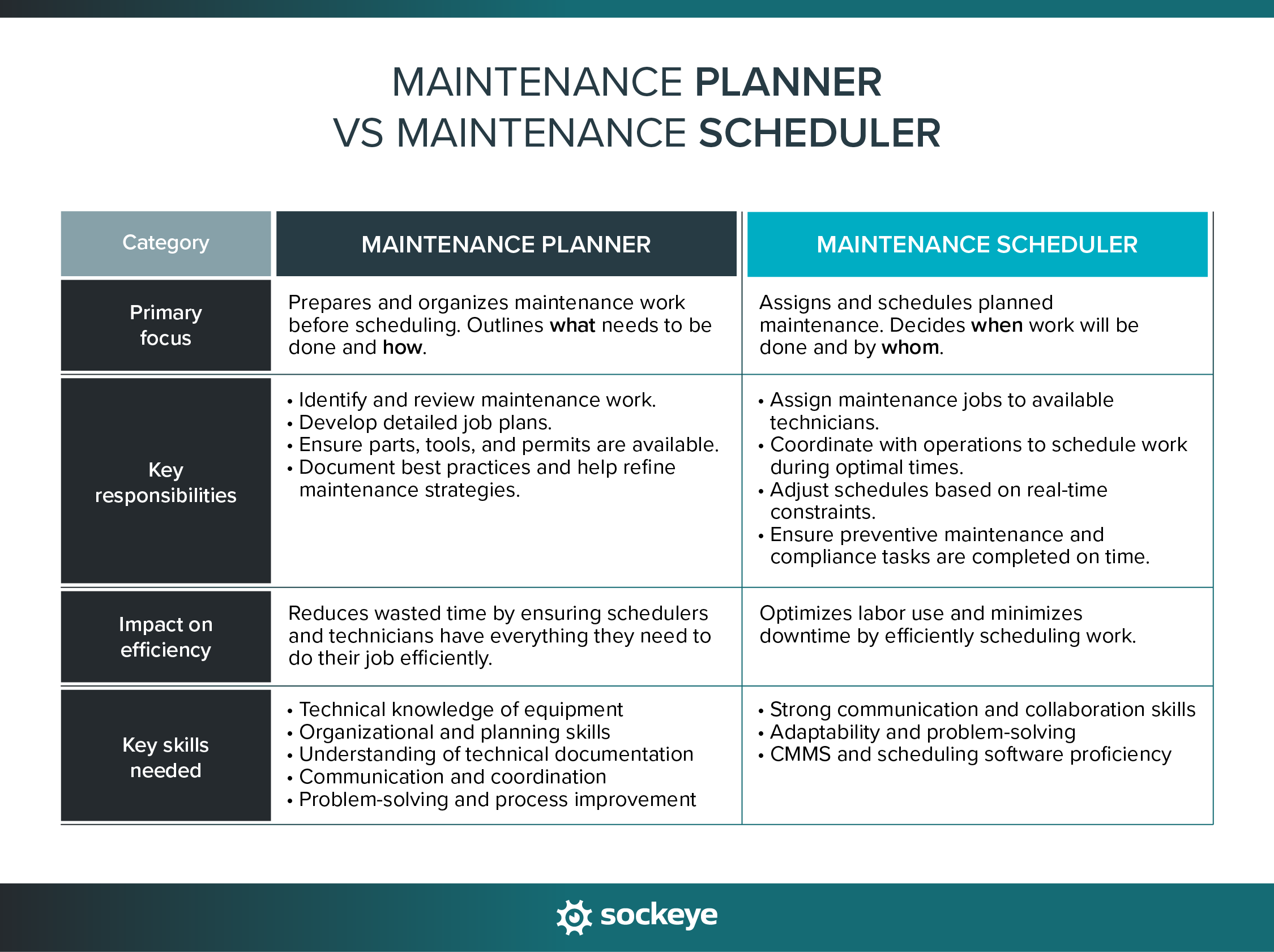

Maintenance planner and maintenance scheduler are two different roles with distinct purposes and responsibilities. The planner focuses on what needs to be done and how to do it, while the scheduler determines when the work will take place and who will do it.

Some maintenance departments, especially smaller ones, combine planning and scheduling into a single role to save costs. When the workload is limited, there might not be enough work to justify separate positions.

Furthermore, organizations believe that merging the roles will streamline communication and decision-making. After all, if one person is responsible for both planning and scheduling, they have complete control over the process. But while this setup may work in some situations, it comes with serious limitations.

The biggest issue is the lack of focus on planning. If a single person is responsible for both planning and scheduling, in reality, they will often end up doing a lot of scheduling and almost no planning.

On top of that — as you will soon see below — planning and scheduling require different skill sets and it is not always easy to find a person that excels in both roles.

TL;DR: While one person can manage both roles for a small operation, larger organizations should separate them to prevent inefficiencies.

The differences between planners and schedulers

Maintenance planners and schedulers play distinct but complementary roles in ensuring that maintenance work is executed efficiently. While both contribute to the overall maintenance process, their responsibilities and skill sets can differ significantly.

These differences are not reflected in salaries. According to PayScale, the median wage for a maintenance scheduler is around $74k, compared to $78k for maintenance planners. It might be because many facilities look at it as a single role.

Larger discrepancies in compensation can arise when facilities tie salaries to performance metrics. However, as one industry expert points out, this can backfire if used too rigidly:

“Tying supervisor pay to schedule compliance makes the supervisor cringe whenever a hiccup causes an emergency work order. The supervisor must then decide whether to help the plant by breaking the weekly schedule or to help his own family by adhering to the weekly schedule.”

The role and responsibilities of maintenance planners

Planners focus on what needs to be done, how it should be done, and what materials and resources are required. They make sure that maintenance work is well-prepared before it reaches the scheduling phase and provide technicians with everything they need to complete jobs effectively.

Key responsibilities of a maintenance planner include:

- Identifying maintenance work: Review incoming work requests, verify the issue, and determine whether the task requires detailed planning. Minor routine tasks may be straightforward, while others need extensive preparation.

- Developing work plans: Create step-by-step instructions for maintenance tasks, ensuring technicians have clear guidance. This includes specifying required tools, spare parts, safety measures, and estimated time for completion.

- Managing parts and resources: Collaborate with procurement to ensure parts and tools are ordered in advance and on hand before a job starts. This helps prevent delays caused by missing materials or last-minute orders.

- Improving maintenance procedures: Analyze past work orders and technician feedback to refine job plans and eliminate inefficiencies. Identify recurring maintenance issues and recommend preventive actions to reduce future breakdowns.

- Supporting continuous improvement: Work alongside reliability engineers to optimize preventive maintenance strategies. Provide insights into failure trends and suggest ways to improve asset reliability.

A maintenance planner’s role is all about preparation. When they do a good job, it makes life easier for schedulers and technicians.

The role and responsibilities of maintenance schedulers

A maintenance scheduler ensures that planned maintenance work is assigned to the right people at the right time with minimal disruption to operations. Their goal is to maximize efficiency by optimizing labor availability, equipment downtime, and work prioritization.

Key responsibilities of a maintenance scheduler include:

- Scheduling maintenance work: Assign planned jobs to technicians based on priority, available labor, and equipment downtime windows. Ensure that critical tasks are completed first while balancing preventive and corrective maintenance.

- Coordinating with operations: Work with production teams to schedule maintenance work during the least disruptive times. Ensure that critical assets remain operational when needed and that downtime is planned efficiently.

- Optimizing workforce utilization: Assign tasks based on technician skills, availability, and workload. Avoid overloading technicians while ensuring that work hours are used effectively.

- Adjusting schedules as needed: Respond to unexpected issues such as emergency repairs, technician absences, or changes in production schedules. Update maintenance schedules accordingly.

- Monitoring work progress: Track maintenance jobs in real-time to ensure they are completed on schedule. Identify delays or bottlenecks and keep them in mind while developing new schedules.

By effectively scheduling maintenance work, schedulers ensure that maintenance is carried out efficiently, minimizing downtime and maximizing productivity.

Top 5 skills a maintenance planner should have

A successful maintenance planner needs a mix of technical expertise, organizational skills, and problem-solving abilities.

Key skills of a maintenance planner include:

- Technical knowledge of equipment and maintenance processes: Understands asset functionality, failure modes, and repair best practices. Familiar with mechanical, electrical, and hydraulic systems, OEM manuals, and reliability-centered maintenance.

- Strong organizational skills: Gets their job done in a constantly changing environment with various constraints. Able to weigh multiple factors before making a decision.

- Ability to interpret technical documentation: Reads schematics, engineering drawings, and work order histories to create accurate job plans. Updates procedures and checklists based on past maintenance data.

- Communication skills: Works with technicians, supervisors, procurement teams, and production staff to ensure work is planned correctly. Prevents delays by aligning maintenance with operations and ensuring all materials are ready.

- Problem-solving mindset: Identifies inefficiencies and analyzes past failures to improve future job planning. Adapts plans based on technician feedback and equipment performance trends.

Top 3 skills a maintenance scheduler should have

In contrast to the planner, the maintenance scheduler doesn’t need to have strong technical skills or know how to do the job. It is probably the biggest difference between the two. Instead, they should be a good coordinator that is intimately familiar with maintenance scheduling best practices.

Key skills of a maintenance scheduler include:

- Collaboration and communication: Works closely with maintenance planners, technicians, and production teams to align schedules with operational needs. Clearly communicates job assignments and adjusts plans based on real-time constraints.

- Adaptability: Quickly responds to unexpected breakdowns, labor shortages, or changes in production schedules without getting stressed out or bogged down in details.

- Proficiency with using digital tools: Can quickly learn how to use maintenance scheduling software to schedule work, track job progress, and communicate schedule changes.

The relationship between planning and scheduling

Maintenance work needs to be planned, then scheduled, then executed. Without proper planning, scheduling becomes a guessing game, leading to inefficiencies and delays in work execution.

Most maintenance jobs should be planned — but not all

Planning is crucial for most maintenance tasks, especially those that involve multiple steps, specialized tools, or specific safety protocols. However, there are minor tasks that don’t require detailed planning.

Example:

- Changing a lightbulb doesn’t need a maintenance planner to create a detailed work order. The technician can just grab a bulb and replace it.

- But what if the issue isn’t just the bulb? What if the fixture is damaged, the wiring is faulty, or the voltage supply is inconsistent? Now, it’s no longer a simple swap. The technician might need to replace the entire fixture, ensure they have the right parts, check wiring diagrams, and follow safety protocols. This requires planning to avoid delays or extra trips to the storeroom.

In other words, there are simple maintenance tasks where it is hard to justify having a maintenance planner spend their valuable time on.

The planning effort isn’t always proportional to the size of the job

The size of a maintenance job doesn’t necessarily dictate how much planning effort it requires. A two-hour job might require more preparation than an eight-hour job.

Example:

- A two-hour job to replace a faulty valve in a high-pressure system might require extensive planning—ordering a replacement, arranging permits, draining the system, and ensuring safety procedures are followed.

- Meanwhile, an eight-hour job like inspecting and cleaning an HVAC system across multiple rooms may be routine, with only minimal planning needed to ensure technicians have access and the right tools.

In both scenarios, proper planning ensures that maintenance work is executed efficiently, with minimal downtime and no unnecessary delays. Once the plan is in place, scheduling can take over to assign the personnel based on their skills and availability.

How Sockeye supports maintenance schedulers

Efficient maintenance scheduling can be a challenge, especially when balancing technician availability, production constraints, and unexpected breakdowns. This is where Sockeye comes in.

Sockeye is a simple CMMS add-on designed to help organizations streamline their scheduling process. If you already have a CMMS and you are not satisfied with its scheduling functionality, Sockeye is the solution for you.

Our scheduling app offers a two-way integration with any CMMS software you might be using. This way, you can use our intuitive interface to easily assign work orders, track job progress, and adjust schedules in real time.

How Sockeye makes life easier for maintenance schedulers:

- Simplifies scheduling decisions: Sockeye’s scheduling automation helps assign the right work to the right technician based on their skills and availability.

- Improves visibility and coordination: With real-time insights, schedulers can see technician availability, job progress, and potential delays, making it easier to adjust schedules as needed.

- Optimizes workforce utilization: Prevents technician underutilization or overload by balancing workloads and prioritizing critical tasks.

- Reduces scheduling conflicts: You can create a live, verified schedule that keeps everyone on the same page. This helps prevent overlapping work orders and minimizes disruptions to production.

- Enhances communication: Sockeye enables better collaboration between planners, schedulers, and technicians by providing a centralized platform for work order management.

With Sockeye, maintenance scheduling becomes faster, more efficient, and less stressful, allowing teams to focus on keeping equipment running smoothly instead of fighting scheduling conflicts.Want to see if Sockeye is right for you? Schedule a demo today!