Planned maintenance plays a huge role in extending the life of machines, reducing unexpected failures, and keeping operations efficient. The difference between a well-planned maintenance strategy and a reactive one can mean thousands (or even millions) of dollars saved in downtime and repair costs.

In this article, we’ll break down everything you need to know about planned maintenance — what it is, the different types, and how to set up a planned maintenance program while avoiding common mistakes.

Whether you’re a maintenance manager or just looking to optimize your team’s approach, this guide will help you get the most out of your maintenance strategy.

What is planned maintenance?

Planned maintenance is a proactive approach to maintaining equipment, where maintenance tasks are planned and scheduled in advance to prevent failures and minimize unplanned downtime. Instead of reacting to breakdowns as they happen, planned maintenance ensures that work is done at the right time — whether it’s inspections, servicing, or part replacements.

The key benefit of planned maintenance comes in the form of cost savings. Be it construction, IT, or manufacturing, planned downtime is orders of magnitude cheaper than unplanned downtime.

When equipment unexpectedly fails, production stops and emergency repairs and inventory orders are needed. There are numerous overhead costs that quickly add up. However, when maintenance is scheduled in advance, parts can be ordered ahead of time, labor can be assigned efficiently, and operations can plan around equipment availability.

Planned maintenance also helps with safety, compliance, and operational efficiency. Well-maintained machines are less likely to cause accidents, and many industries have strict regulations requiring routine maintenance.

Two types of planned maintenance

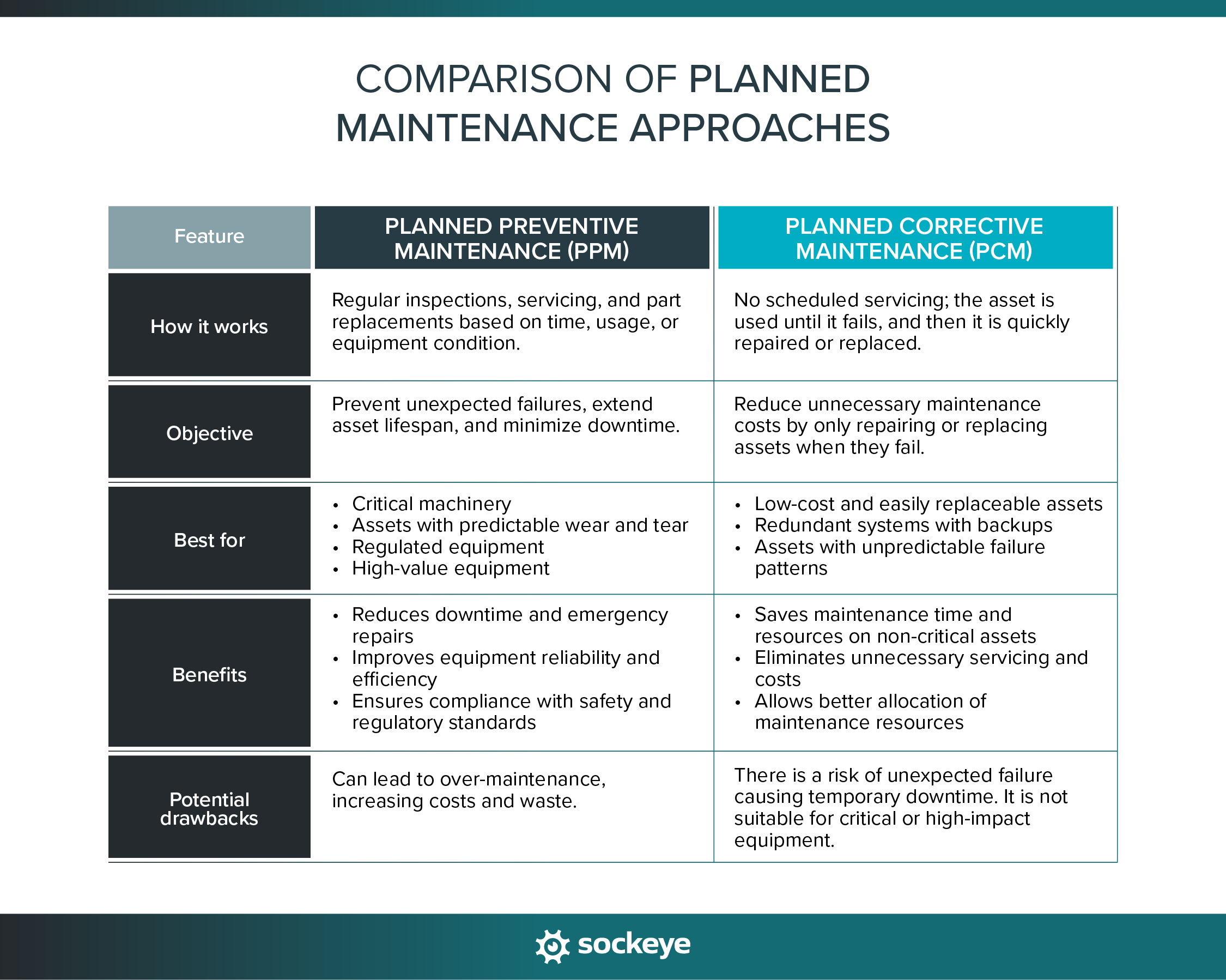

Not all equipment requires the same type of maintenance. Some assets need regular servicing to keep them running smoothly, while others can be left to run until they break. Planned maintenance can be applied in both situations using either Planned Preventive Maintenance (PPM) or Planned Corrective Maintenance (PCM).

Planned preventive maintenance

Planned preventive maintenance is all about preventing failures before they happen. It involves scheduled inspections, servicing, and part replacements at regular intervals to keep equipment running smoothly.

It works great for:

- Critical machinery: Equipment that would cause major disruptions if it failed (e.g., production lines, conveyor systems).

- Assets with predictable wear and tear: Machines with moving parts that degrade over time (e.g., motors, pumps, vehicles, HVAC systems).

- Regulated equipment: Assets that must meet safety or compliance standards (e.g., fire suppression systems, medical devices).

- High-value equipment: Machines that are expensive to repair or replace (like CNC machines or turbines).

An example of planned preventive maintenance:

Imagine a manufacturing plant that relies on conveyor belts to move materials between workstations. If a belt motor fails unexpectedly, the entire production line could be shut down.

To prevent this, the maintenance team builds an equipment schedule that includes monthly inspections to check for belt wear, lubrication levels, and motor function. Every six months, they replace key components like bearings and belts — even if they haven’t failed yet.

Planned corrective maintenance (a.k.a. planned breakdown maintenance)

Planned corrective maintenance, also known as run-to-failure maintenance, is when an asset is intentionally allowed to operate until it fails. However, unlike reactive maintenance, failure is expected and planned for — meaning the maintenance team has a plan in place to repair or replace the asset quickly and efficiently.

This approach works best for assets whose unexpected failure won’t significantly impact operations:

- Low-cost and easily replaceable assets: Items that are cheaper to replace than to maintain (think light bulbs, small motors, non-critical sensors).

- Redundant systems: Equipment that has backups or alternatives in place (e.g., secondary HVAC units, backup pumps).

- Assets with unpredictable failure patterns: Machines where preventive maintenance wouldn’t significantly reduce failures (as with some electronics and certain hydraulic components).

An example of planned corrective maintenance:

A factory uses multiple cooling fans to regulate the temperature of electrical enclosures. Since each enclosure has multiple fans, a single fan failure won’t cause an immediate problem. Instead of performing routine maintenance on each fan, the plant lets them run until they break.

When a fan fails, the maintenance team quickly swaps it out with a spare that’s already in stock, minimizing downtime. Because these fans are inexpensive and easy to replace, planned corrective maintenance is the most efficient and cost-effective approach.

Typical planned maintenance workflow

A well-structured planned maintenance process ensures that the work gets done properly (on the first try) and in a reasonable amount of time. It also helps when the person planning the jobs has enough experience, as noted by specialist engineering and maintenance trainer, Matthew Laskaj, in a Maintenance Management Podcast:

“I’ve been in projects where we’ve had some really excellent planners who know the software really, really well but they don’t know anything about the job. So what ends up happening is the engineer would have to come and sit next to them on a Monday morning and sit down with them for two hours telling that planner exactly what tasks go where, how long, it’s going to take, what’s going to be needed and all that personal planner would do is input stuff into the computer.

So I think, for a good maintenance plan or good planning process, have someone who knows the job really, really well before the other side of it’s done.”

While the details may vary by industry, the planning workflow generally follows four key phases:

- Identify: Determine which assets require maintenance and what type of work needs to be done. This can be based on equipment history, manufacturer recommendations, or condition monitoring data.

- Plan: Gather and review the necessary resources, such as spare parts, tools, and personnel, to complete the maintenance work.

- Schedule: Assign a specific time for maintenance tasks to minimize disruption to operations. Scheduling can be based on usage, time intervals, equipment condition, or predictive insights.

- Execute: Perform the maintenance work as planned, document the process, and track any issues that arise.

- Follow-up/Review: Verify that the maintenance was completed correctly, review technician notes (if any), and adjust future plans if needed.

Example of a planned maintenance workflow in a manufacturing plant

A manufacturing facility relies on a fleet of forklifts for material handling. To ensure they remain in good working condition, the maintenance team follows a standardized planned maintenance workflow:

- Identify: The business knows that forklifts are critical to their process and need to be regularly maintained — so the asset is put on a preventive maintenance plan.

- Plan: The maintenance team orders oil, replacement batteries, and tires in advance, ensuring everything is ready when the work is scheduled.

- Schedule: Maintenance is scheduled for off-peak hours to avoid disrupting operations. Each forklift is assigned a specific slot for servicing.

- Execute: The team performs oil changes, battery checks, and tire replacements as scheduled, keeping records of each service.

Steps for building a planned maintenance program

The process starts with understanding your assets, deciding which maintenance approach works best for each, and then building schedules and procedures to keep everything on track.

In this section, we’ll walk through five key steps to help you build a successful planned maintenance program.

1. List all of your assets

The foundation of a solid planned maintenance program is knowing what equipment you have and its condition.

Start by creating a centralized asset database that includes:

- Asset name and location: Identify where each piece of equipment is located in your facility and give it a unique identifier.

- Manufacturer and model details: Useful for ordering parts and following recommended maintenance schedules.

- OEM manuals, purchase date and lifecycle status: Helps estimate when replacements or major overhauls might be needed.

- Maintenance history: Keeping track of past maintenance helps in identifying trends and potential future failures.

This list can be managed in a simple spreadsheet or a computerized maintenance management system (CMMS), depending on the complexity of your operations. This can significantly simplify your maintenance planning process.

2. Match assets with the type of planned maintenance approach

Once you have a complete list of your assets, the next step is to decide which maintenance approach works best for each one.

To make this decision, consider factors like:

- Criticality: If an asset fails, will it cause major downtime or safety risks?

- Cost of failure: Is it cheaper to repair/replace the asset or maintain it regularly?

- Predictability of failure: Does the asset have known wear-and-tear patterns?

- Regulatory requirements: Are there compliance or safety standards requiring preventive maintenance?

This will help you decide if an asset should be on a preventive maintenance schedule or a run-to-failure program.

3. Develop schedules and procedures for planned preventive maintenance

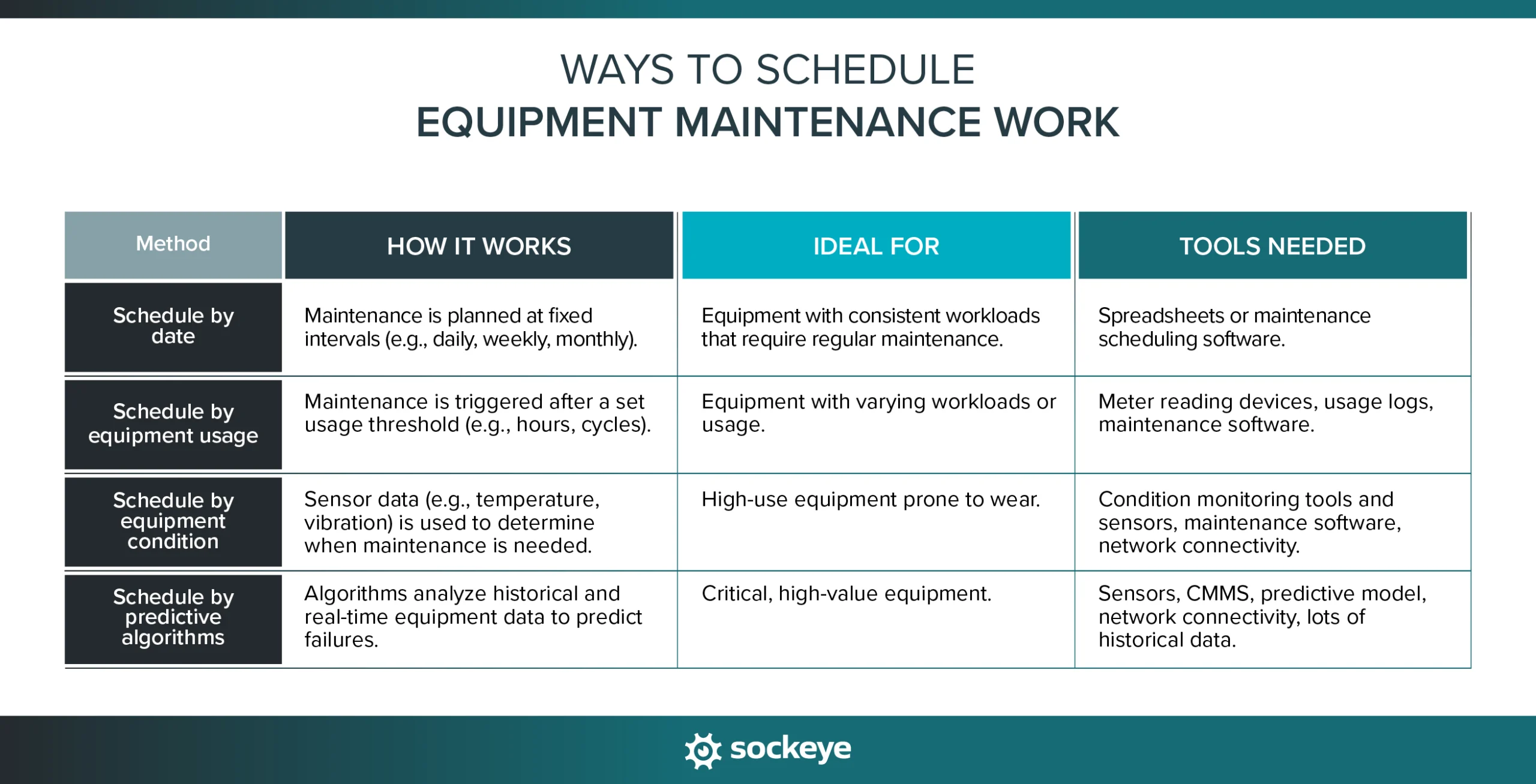

For each asset that ends up on a preventive schedule, you will want to determine:

- Maintenance frequency: How often should the task be performed? (Daily, weekly, monthly, annually)

- Trigger type: Will maintenance be scheduled based on time (calendar-based) or usage (e.g., every 500 machine hours)?

- Required tasks: What specific inspections, servicing, or part replacements need to be done?

- Responsible personnel: Who will perform the maintenance? (In-house team, external contractors)

As you can see in the image below, there are several different, viable approaches to maintenance scheduling.

Standardization is a great way to improve speed, quality, and consistency. Work with your most experienced technicians to define best practices and create step-by-step checklists for recurring inspections, servicing, and part replacements. You can do the same with maintenance prioritization, planning, and scheduling processes.

4. Create procedures and plan of action for planned corrective maintenance

Some assets will be left to run to failure. For those, you should have procedures to repair or plans to replace the asset — to minimize downtime when the equipment eventually fails.

You’ll want to:

- Stock spare parts: Keep replacement parts on hand to avoid long wait times when the failure occurs.

- Define response procedures: Establish clear steps for diagnosing failures, obtaining replacement parts, and making repairs.

- Have a replacement plan: If the asset will need to be replaced, you should have a plan for that. The more complicated and expensive the replacement is, the more detailed plan you should have.

- Assign responsibilities: This is important to do if external vendors might be needed. If any of your maintenance techs can do it, then you do not have to assign someone ahead of time.

Imagine you have a bunch of exhaust fans installed throughout the facility that you do not regularly maintain — just replace when they fail. In such a case, you should have a small stock of replacement fans in inventory at all times, develop a quick swap-out procedure, and log failure data to track how long each fan lasts, helping the team make better (and more timely) purchasing decisions.

5. Execute, track, adjust

Once your planned maintenance program is in place, the final step is putting it into action, tracking its performance, and making necessary adjustments. Even the best maintenance plans need fine-tuning over time to keep up with changing operational needs.

Ideally, you would use tools like CMMS and Sockeye to create and share maintenance schedules in a digital form and keep the whole team on the same page.

You can use those same tools to track key maintenance performance indicators and identify areas for improvement. Metrics like schedule compliance, MTBF and MTTR, maintenance backlog, and hours spent on corrective vs preventive work, are worth keeping an eye on.

Common mistakes to avoid when running planned maintenance

In this section, we’ll quickly break down the most frequent mistakes maintenance teams make — and discuss how to avoid them.

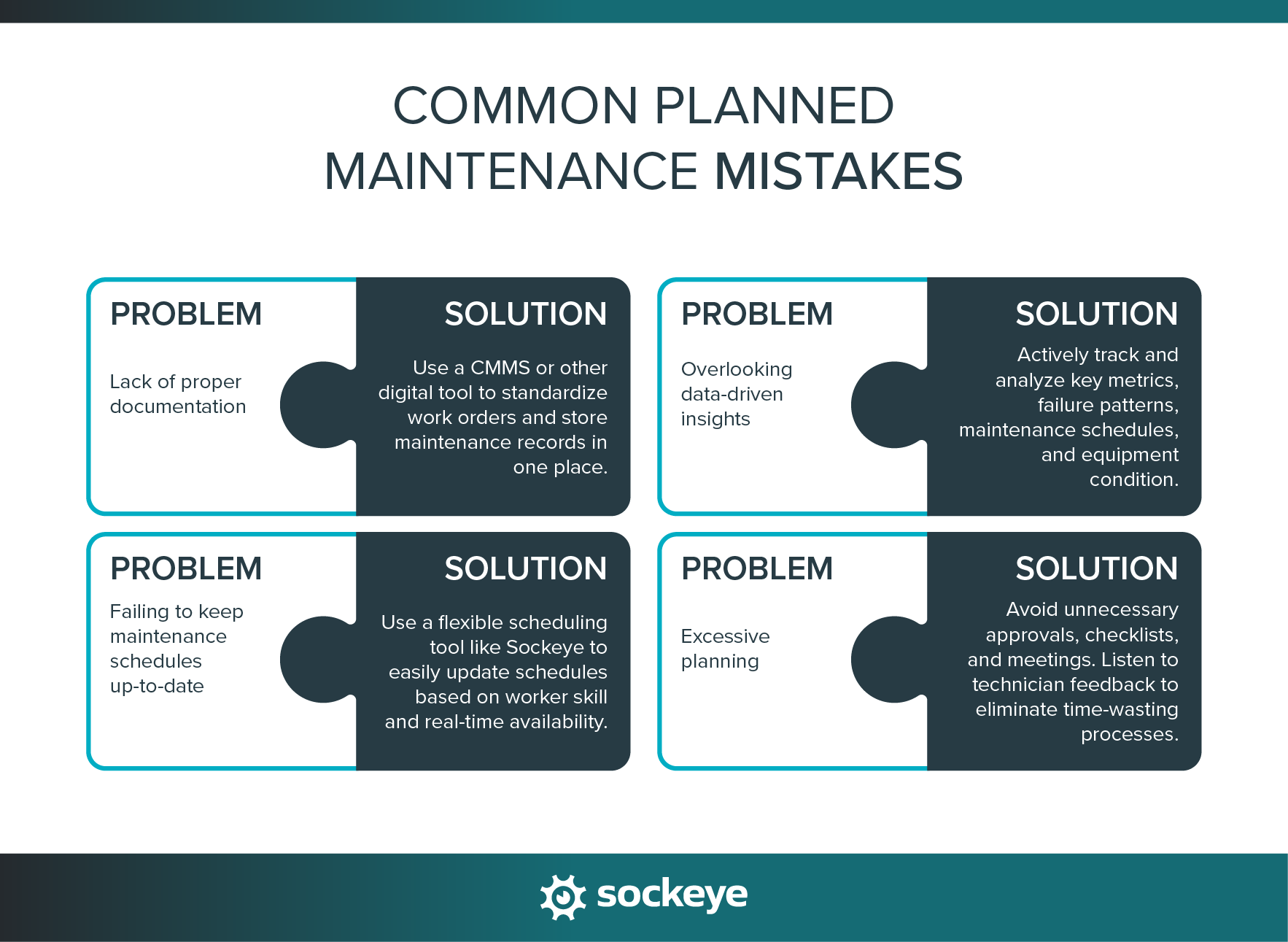

Lack of proper documentation

If maintenance records are incomplete, outdated, or scattered across multiple sources, it becomes difficult to track asset history, plan and schedule tasks efficiently, or diagnose recurring issues. This leads to missed maintenance, unplanned downtime, and wasted resources.

To avoid this, ensure all maintenance activities are properly documented and easily accessible.

Use a CMMS or a similar digital tool to keep all maintenance records in one place, making it easier to track work history and plan future tasks. Plus, create a standardized work order template to assign work and log completed maintenance — including date, task performed, parts used, and technician notes.

Overlooking data-driven insights

Many maintenance teams focus on completing tasks without taking the time to analyze maintenance data.

We understand why that happens — there is a lot of work to do and getting accurate data is not always easy. But not doing it is a missed opportunity for improvement. You will be at greater risk of overspending on unnecessary maintenance and overlooking simple changes that could boost productivity.

Again, you will want to track relevant KPIs, regularly review maintenance logs to identify patterns, and extend or shorten maintenance intervals based on failure rates. If you have the budget for it, installing condition-monitoring sensors on critical equipment will help your team plan and schedule work more effectively.

Failing to update maintenance schedules

With the right tools, maintenance teams do not have a lot of issues setting up an initial preventive maintenance schedule. The problem is that they do not adjust them nearly often enough — to match equipment usage, environmental conditions, or production demand changes.

So they end up over or under maintaining equipment and battling with unplanned downtime.

From our experience, this has two main causes. First, they do not have enough data to make those adjustments — you can refer back to everything we talked about in the previous section.

The second problem is of a technical nature. The tool they use to schedule work, be it CMMS or Excel, makes it hard or convoluted to update the schedule on the fly.

The easiest way to fix that is to use a more intuitive and flexible work order scheduling tool like Sockeye. It connects to your existing CMMS and workforce management software and helps you create and update schedules in a couple of clicks based on real-time technician availability.

Excessive planning

While planning is essential for effective maintenance, some teams overcomplicate the process. Spending too much time perfecting schedules, checklists, and procedures can slow down actual maintenance work, making it harder to stay productive.

Common signs of excessive planning include:

- Creating overly detailed maintenance plans that require constant adjustments.

- Documenting every minor task and action to the point where technicians spend more time on paperwork than actual repairs.

- Requiring unnecessary approvals before performing routine maintenance, causing delays.

- Having overly frequent team meetings in which you reiterate stuff everyone already knows.

The solution? Do less of that. Take a step back and review if you are asking your team to do stuff that doesn’t add value — like entering specific data/metrics that are never used. Also, listen to complaints. While it is not a given, multiple complaints about the same issues are worth looking into.

Schedule more work to get more work done

Effective maintenance isn’t just about fixing problems — it’s about managing time efficiently. When maintenance work is properly scheduled, teams can:

- Reduce idle time: Technicians know exactly what tasks need to be done and when.

- Minimize equipment downtime: Maintenance is planned around production schedules to avoid unnecessary disruptions.

- Improve resource allocation: Labor, spare parts, and tools are assigned efficiently, avoiding last-minute scrambles.

Managing planned maintenance manually is not feasible, especially for large teams and complex operations. That’s where Sockeye comes in. It helps:

- Automate work order scheduling, making sure the weekly scheduling can be done in minutes instead of hours.

- Optimize technician workloads, ensuring the techs with the right qualifications are assigned to the right jobs and that their schedule is full.

- Track and adjust schedules in real-time, keeping teams agile and responsive.

By using a smart scheduling tool like Sockeye, maintenance teams can increase efficiency, reduce unplanned downtime, and get more work done — without overloading technicians.

📅 Schedule a demo today and make sure that all of the planned work actually gets done!